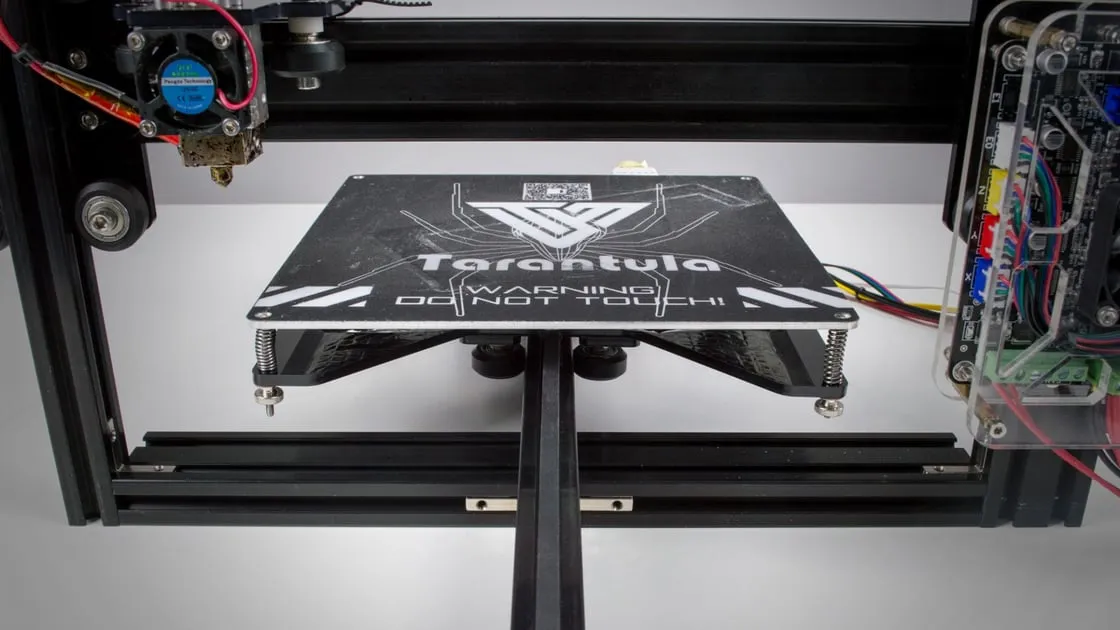

Understanding the Tevo Tarantula Hot End Assembly

The Tevo Tarantula is a popular 3D printer known for its affordability and ease of use. However, like any 3D printer, understanding its components is crucial for maintenance and optimal printing results. The hot end is a critical component of the Tevo Tarantula, as it’s responsible for melting and extruding the filament. A properly assembled hot end ensures consistent filament flow, reduces the chances of clogs, and contributes significantly to the quality of your prints. Incorrect assembly, on the other hand, can lead to a host of issues, from failed prints to damage to the printer itself. This guide will walk you through the essential aspects of the Tevo Tarantula hot end assembly, providing valuable tips to ensure a smooth and successful printing experience. We’ll break down the key parts, offer expert assembly advice, and troubleshoot common issues to empower you to become a true 3D printing expert.

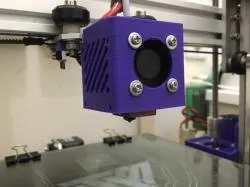

Key Components of the Hot End

Before diving into the assembly, it’s essential to understand the primary components of the Tevo Tarantula hot end. Knowing these parts and their functions will make the assembly process much clearer and help you troubleshoot issues later on. Each part plays a specific role in the melting and extrusion process. A good understanding of each of these components is vital for successful hot end assembly and a better 3D printing experience.

Nozzle

The nozzle is the tip of the hot end, where the molten filament exits. It’s usually made of brass or hardened steel, and the size (diameter) of the nozzle affects print resolution and speed. Different nozzle sizes can be used for various print requirements. It is essential to choose the correct size for your needs and print settings. Always make sure that the nozzle is clean and free from any obstructions, which can lead to printing failures. Regular cleaning and maintenance of the nozzle are critical to achieving high-quality prints.

Heating Block

The heating block is a metal block that houses the heater cartridge and the thermistor. Its primary function is to heat the nozzle to the required temperature for melting the filament. The heating block design ensures even heat distribution to the nozzle. The quality and design of the heating block influence how effectively heat transfers to the filament, significantly impacting print quality. The right heating block is essential to ensure efficient and consistent printing.

Thermistor and Heater Cartridge

The thermistor monitors the temperature of the heating block, while the heater cartridge provides the heat. The thermistor sends temperature data to the printer’s control board, which regulates the power to the heater cartridge to maintain the set temperature. Correct placement of the thermistor and heater cartridge is critical for accurate temperature control and preventing thermal runaway. These components work in tandem to provide consistent heating and prevent printing issues such as under-extrusion or overheating. Choosing high-quality components contributes to overall print quality.

Heat Break or Throat

The heat break, also known as the throat, is a crucial component that separates the hot and cold zones of the hot end. It’s a tube that connects the heating block to the cold end (where the filament enters). Its design prevents heat from traveling up the filament, which can cause jams. A well-designed heat break is crucial to prevent heat creep and filament jams. Proper installation and maintenance of the heat break are critical for smooth printing and prevent many common 3D printing problems. Consider upgrading the heat break for high-temperature filaments to enhance the reliability of your prints.

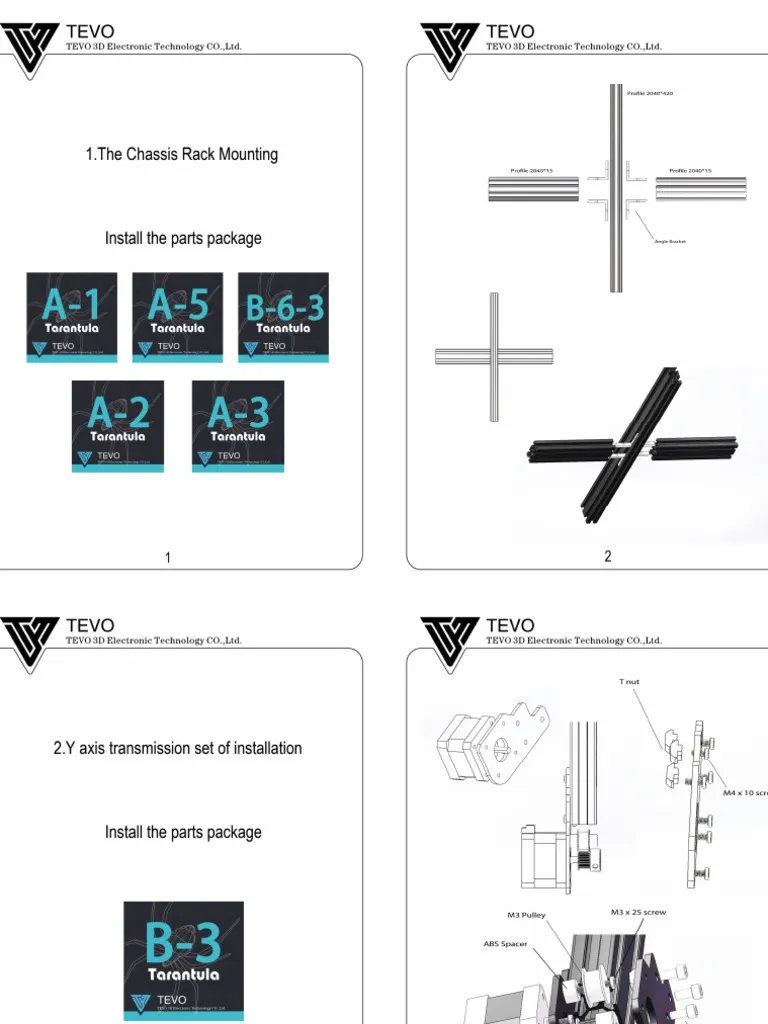

The 7 Top Tips for Assembly

Assembling the hot end correctly is paramount for ensuring your Tevo Tarantula operates efficiently. By following these top 7 tips, you’ll be well on your way to successful 3D printing. These tips cover everything from preparation to final calibration, ensuring you have a solid foundation for printing. Taking your time and paying attention to each detail will greatly improve your print quality and reduce frustration. Remember, the goal is to achieve a smooth, reliable printing process, which begins with a correctly assembled hot end.

Tip 1 Prepare Your Workspace

Before you even touch your Tevo Tarantula, clear a well-lit workspace. Gather all necessary tools and components, and keep them within easy reach. This preparation minimizes interruptions and prevents the loss of small parts. Good lighting is essential for seeing small details, particularly when dealing with the nozzle and thermistor. Organize your workspace to maintain focus and ensure all parts are visible, reducing the likelihood of mistakes. Prepare a clean, clutter-free area before starting your assembly to improve efficiency and reduce errors.

Tip 2 Gather the Right Tools

Having the right tools is essential for any successful assembly. You will need a set of Allen wrenches, a wrench for the nozzle, and possibly pliers for gripping small components. A multimeter can be helpful for testing the thermistor and heater cartridge. Small, precision screwdrivers can also prove useful. Make sure your tools are of good quality to avoid damaging the components. Using the correct tools will make the assembly process easier, prevent damage, and ensure all parts are correctly tightened. A well-equipped toolkit is a 3D printer’s best friend.

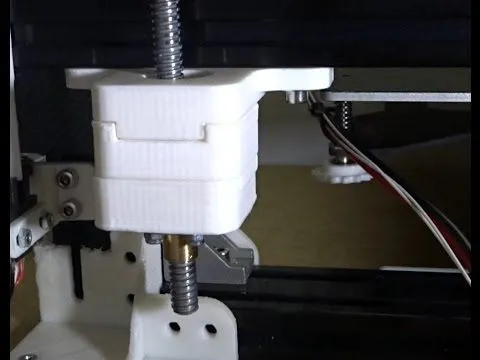

Tip 3 Install the Nozzle Correctly

The nozzle is often the first component to be installed. Ensure the hot end is heated slightly (around 200°C) when installing the nozzle to prevent damage. Tighten the nozzle securely against the heating block. Do not overtighten, which can damage the threads. Make sure the nozzle seats firmly against the heat break to prevent filament leakage. Ensure there are no gaps. Use a wrench specifically designed for nozzles to avoid stripping the threads. Correct nozzle installation is essential for preventing leaks and ensuring proper filament flow. Always check the nozzle before each print session for any wear and tear.

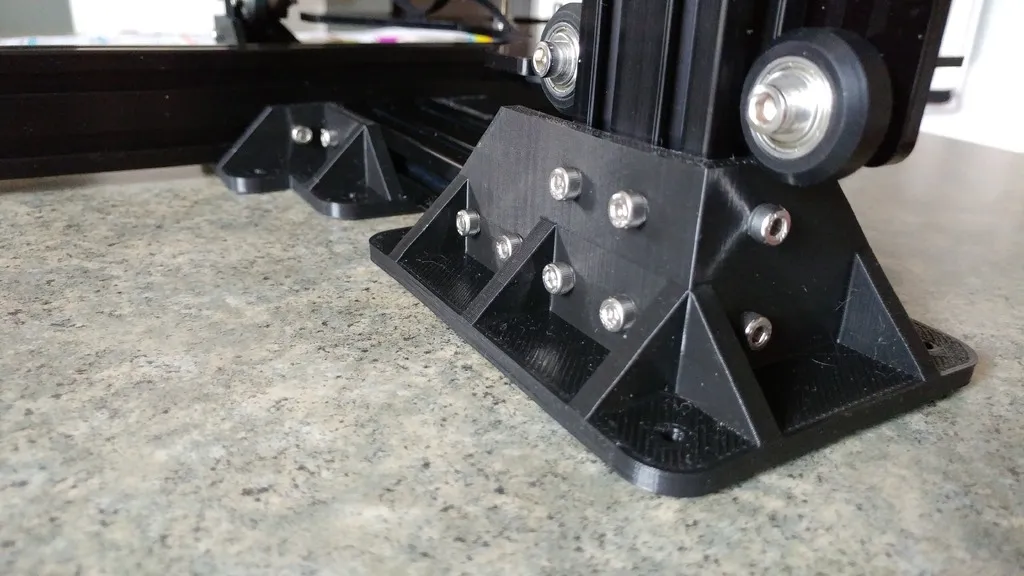

Tip 4 Secure the Heating Block

Properly securing the heating block is critical for maintaining consistent temperatures and preventing thermal runaway. Ensure the heating block is firmly attached to the X-carriage. Check that the screws are tightened but not over-tightened. Over-tightening can damage the heating block or the carriage. Ensure there is no play or movement in the heating block, as this can affect print quality and lead to print failures. A secure heating block is the foundation for temperature stability, which is crucial for high-quality prints.

Tip 5 Proper Thermistor and Heater Cartridge Placement

The thermistor and heater cartridge must be correctly positioned within the heating block for accurate temperature control. The thermistor should make good contact with the heating block, and the heater cartridge should be securely installed. Secure them using set screws or other methods to avoid movement during printing. Incorrect placement can cause inaccurate temperature readings, which will result in poor print quality. Double-check their positions to ensure they don’t interfere with any other components. It’s crucial that the thermistor is seated snugly to ensure accurate temperature readings.

Tip 6 Tighten Screws Systematically

When assembling the hot end, tighten screws in a systematic manner. Start with the screws that hold the heating block and nozzle together. Gradually tighten all screws to ensure even pressure distribution and prevent warping or misalignment. Avoid overtightening any screws, as this can damage the components. Follow a logical sequence, and don’t overtighten. Correct tightening will ensure that all parts are securely held together, preventing leaks and ensuring proper heat distribution. Check all screws after the first few prints to ensure they remain tight due to thermal cycling.

Tip 7 Temperature Calibration

After assembly, it’s essential to calibrate the temperature settings. Use the printer’s control panel or firmware to set the correct temperature for your chosen filament. Use a thermal probe to verify the actual temperature of the nozzle matches the set temperature. Adjust the temperature settings if necessary to ensure accurate printing. Proper temperature calibration ensures the filament melts and extrudes correctly, thus affecting print quality. Accurate temperature calibration is critical to avoid problems like under-extrusion or excessive stringing, thus improving overall print quality.

Troubleshooting Common Issues

Even with careful assembly, you might encounter some common issues. Knowing how to troubleshoot these problems is crucial for maintaining your 3D printer and getting the most out of it. These troubleshooting tips will help you diagnose and resolve common hot end problems, allowing you to keep printing without significant interruptions. Being able to troubleshoot will save you time and ensure you are always printing at your best.

Extruder Issues

Extruder issues often manifest as inconsistent filament flow or complete blockage. Check if the filament is correctly loaded and that the extruder gear is gripping the filament. Check the hot end temperature, nozzle for clogs and filament. Ensure the hot end temperature is appropriate for the filament. Adjust the extruder settings in your slicing software. Extruder issues are a common problem, so a simple fix could be the solution to your issue. Addressing these issues promptly will improve the print quality. These issues can often be related to incorrect hot end assembly.

Temperature Fluctuations

Temperature fluctuations can result in inconsistent prints or even print failures. Check that the thermistor is correctly connected and properly seated within the heating block. Verify that the heater cartridge is functioning correctly. Check the wiring to the heater cartridge and thermistor for any damage. Try calibrating the PID settings of your printer. Temperature fluctuations can significantly affect the print quality, so troubleshooting and correcting this issue is important for achieving great print results. By addressing fluctuations, you will ensure consistent printing.

Filament Jamming

Filament jamming is one of the most frustrating problems. Ensure the heat break is correctly installed and that the hot end temperature is appropriate for the filament. Check for any clogs in the nozzle. Make sure the cooling fan on the hot end is functioning. Consider upgrading to an all-metal hot end if you frequently use high-temperature filaments. Filament jamming can stop your print completely, so it’s important to prevent and address it quickly. By understanding and addressing these issues, you will keep your printer operating at its best.

Maintenance and Further Tips

Regular maintenance and further tips are crucial for maintaining the life and performance of your 3D printer. These maintenance practices will keep your Tevo Tarantula in excellent condition, extend its lifespan, and improve the quality of your prints. Following these tips will lead to a more reliable and enjoyable printing experience, ensuring that your printer is always ready to produce high-quality prints.

Cleaning and Maintenance

Regular cleaning and maintenance can greatly improve the performance and lifespan of your Tevo Tarantula. After each print, clean the nozzle with a brass brush. Periodically inspect the hot end components for wear and tear. Clean the heating block and nozzle regularly to prevent filament buildup. Keep all components clean to ensure reliable operation. Keeping the hot end clean helps to ensure a better quality of print, prevent future problems. Cleaning and maintenance are key to keeping your printer operating effectively.

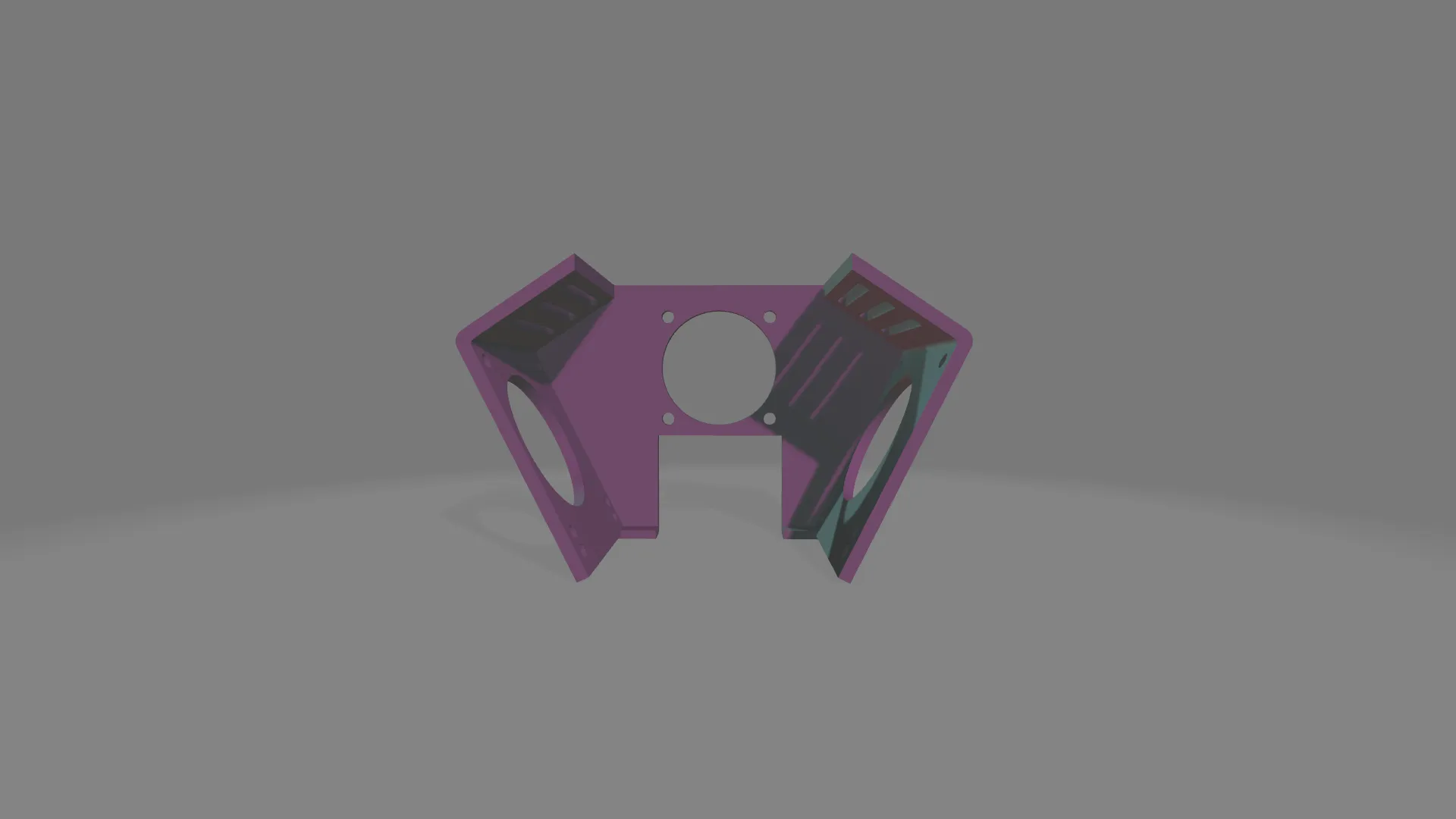

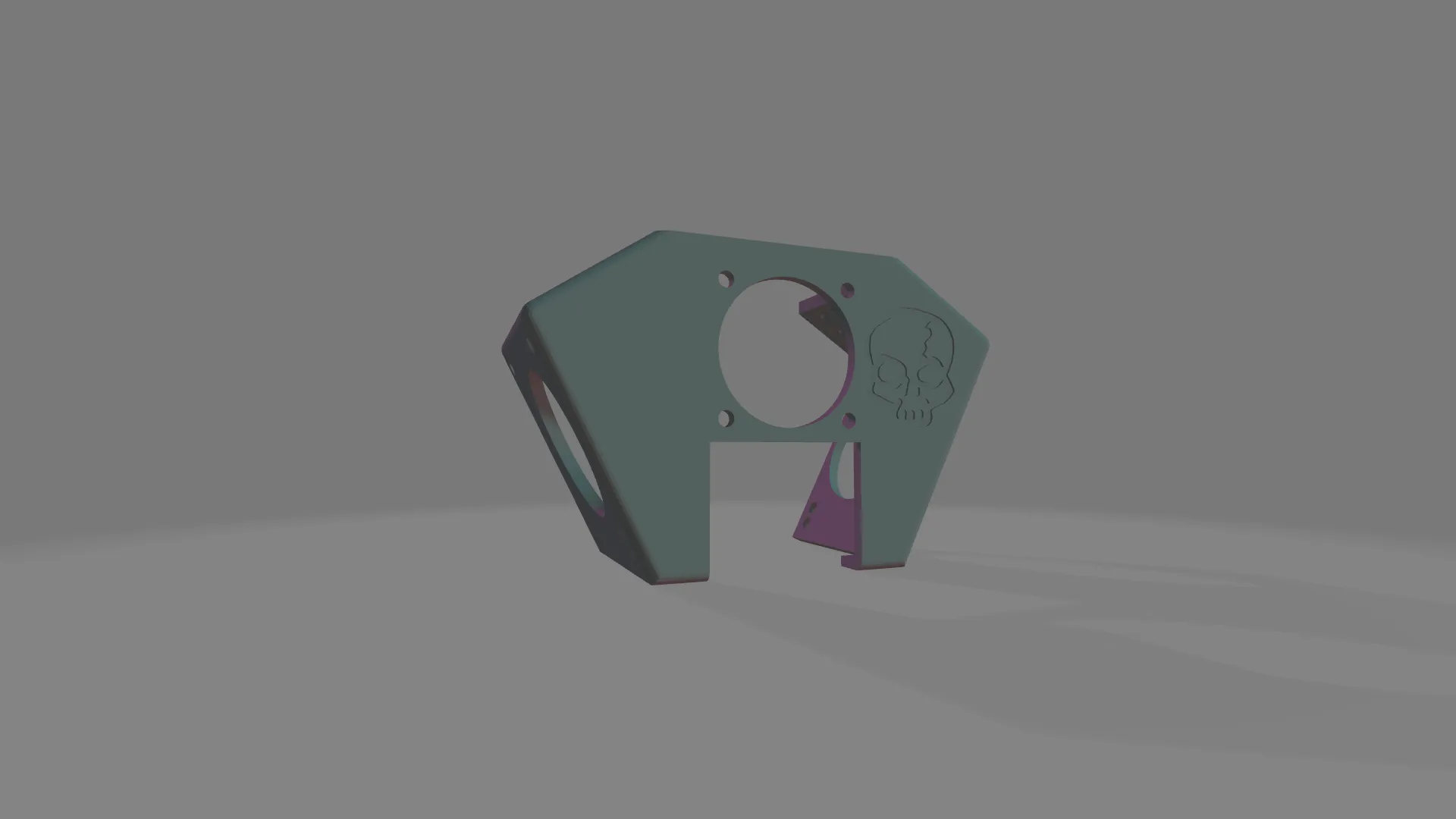

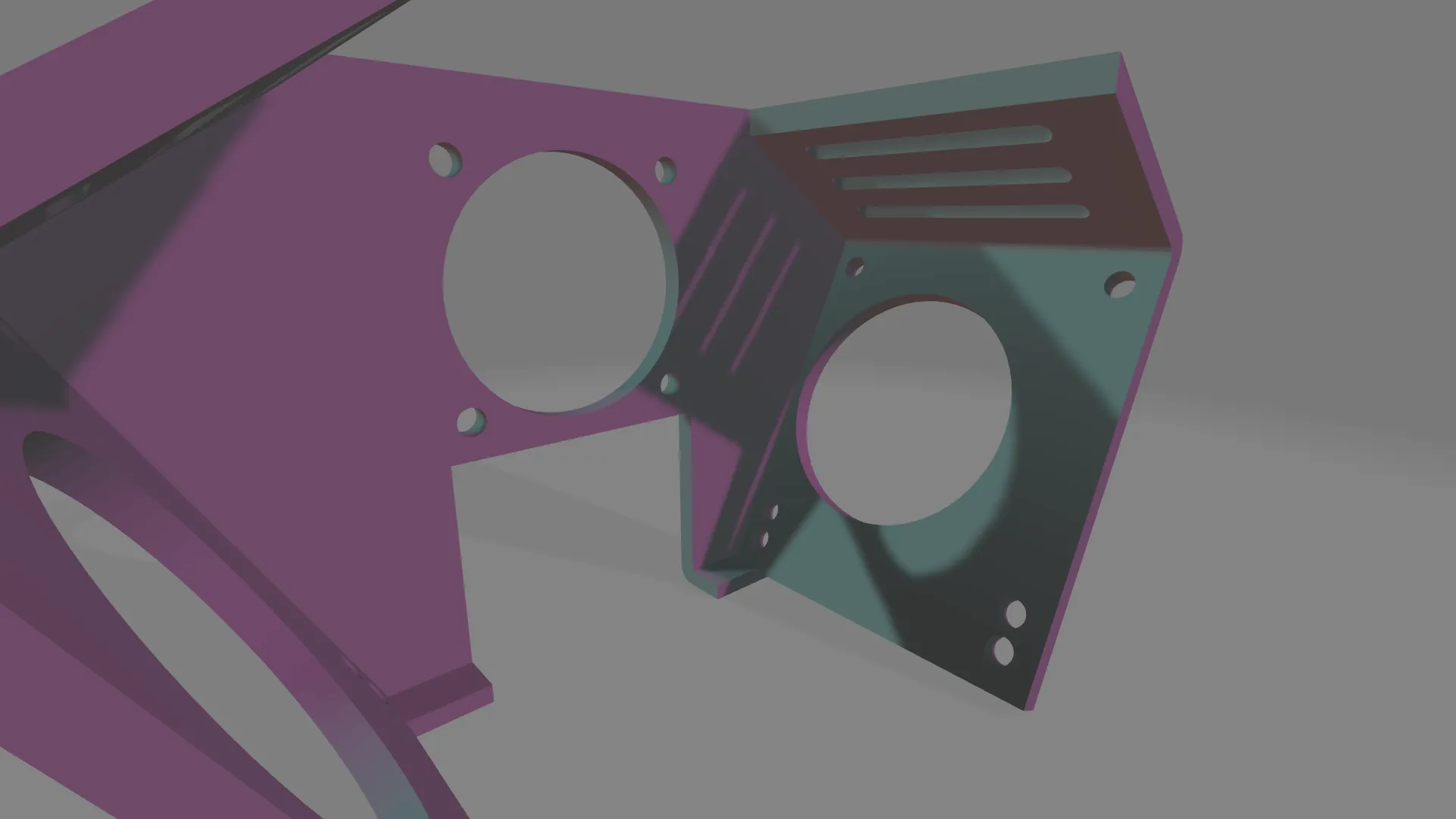

Upgrades and Modifications

Consider upgrades and modifications to improve the printing capabilities of your Tevo Tarantula. Upgrade to an all-metal hot end for improved performance, especially when using high-temperature filaments. Install a silicone sock on the heating block to stabilize the temperature and keep the block clean. Consider upgrading your hot end fan for better cooling performance. Consider upgrading components as they wear out. Experimenting with upgrades can improve print quality and extend the usability of your printer. These modifications can significantly improve your printing experience and output.