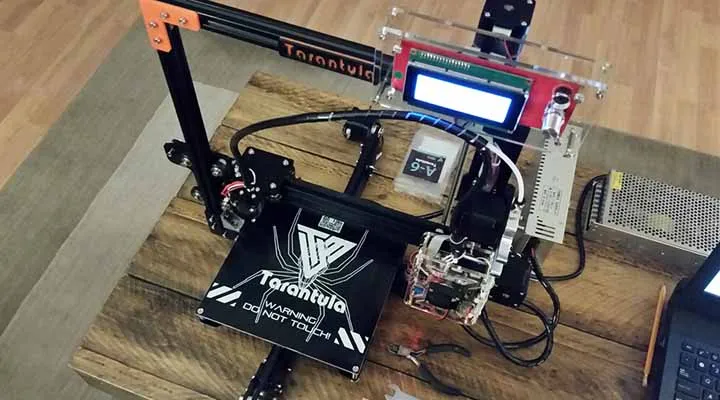

Understanding Off-Center Printing on Your Tevo Tarantula

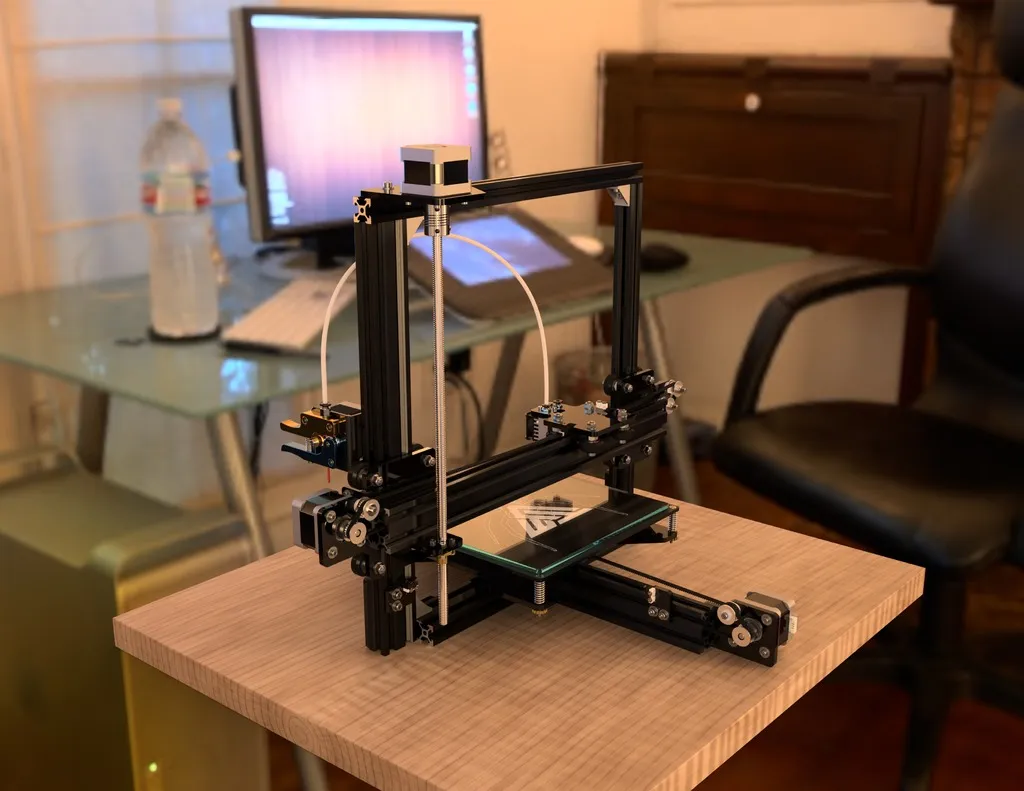

Encountering off-center prints on your Tevo Tarantula can be a frustrating experience, leading to wasted filament and time. When your 3D prints consistently fail to adhere to the center of the print bed, it indicates a problem with the printer’s calibration or mechanical components. This issue disrupts the intended positioning of your 3D models and affects the final outcome of your prints. Identifying the root causes of these issues is essential for getting your 3D prints aligned correctly. This guide aims to unravel the common factors contributing to off-center prints on your Tevo Tarantula, and provide you with actionable steps to ensure your prints are centered on the build plate every time.

Common Causes of Off-Center Prints

Several factors can contribute to off-center prints on your Tevo Tarantula. It is crucial to carefully examine each aspect of your printer and its settings to identify the precise cause of the problem. Understanding the most common factors can save you time and effort during the troubleshooting phase. These elements include but are not limited to print bed alignment, the Z-offset, the condition of belts and pulleys, and the proper functioning of the stepper motors. Other factors such as the slicer settings and the condition of your print bed can also have a huge impact on where your print starts.

Bed Leveling Issues

One of the primary culprits behind off-center prints is an improperly leveled print bed. If the print bed isn’t level, the nozzle’s distance from the bed surface varies across the printing area. This can cause the first layer to adhere poorly or unevenly, pushing the print away from the center. A bed that is too low in one area can cause the nozzle to scrape, while a bed that is too high can result in the filament not sticking. Proper bed leveling is the foundation of a successful 3D printing experience. It ensures that the initial layers of your print adhere correctly to the bed, leading to the formation of a solid base for the rest of the model.

Incorrect Z-Offset

The Z-offset determines the distance between the nozzle and the print bed when the printer starts printing. If the Z-offset is set incorrectly, the nozzle may be too far or too close to the bed. This causes issues with the first layer adhesion, which can also lead to the print starting off-center or lifting from the bed. A Z-offset that is too high might cause the filament not to stick to the bed, and one that is too low can cause the nozzle to scrape the bed, potentially dislodging the print. It is therefore essential to calibrate the Z-offset precisely to promote ideal first-layer adhesion.

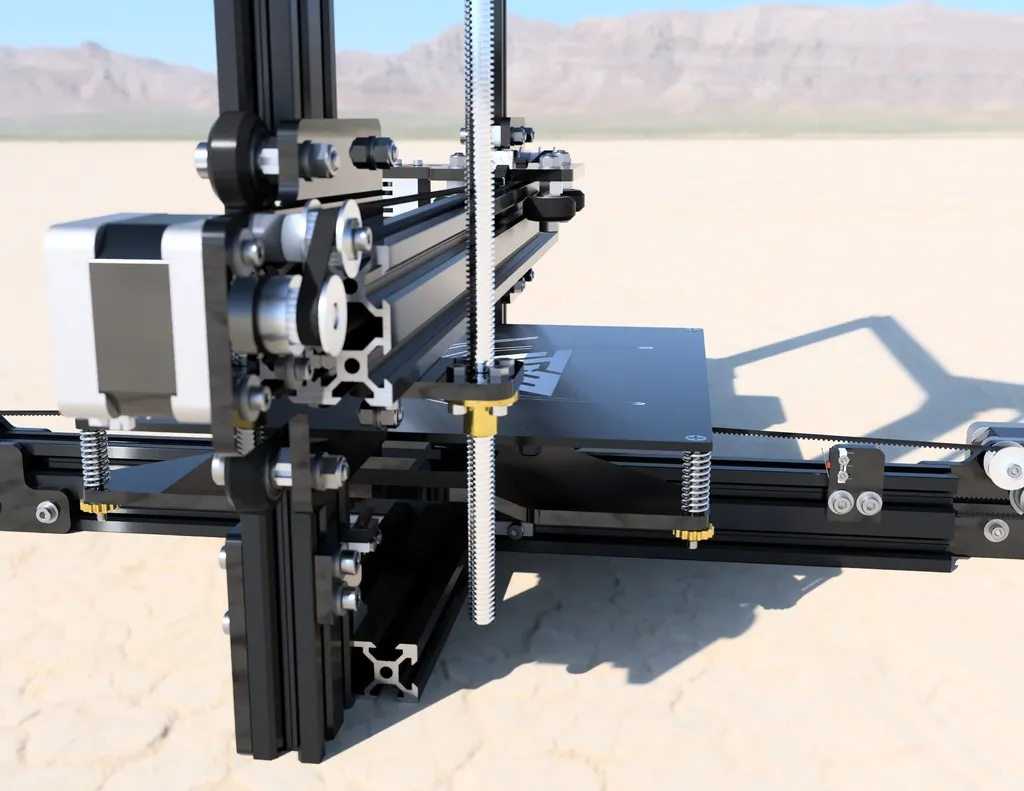

Loose Belts

Loose belts are a common mechanical issue that leads to off-center prints. The belts control the movement of the print head across the X and Y axes. If the belts are too loose, the print head can slip or move inaccurately, leading to misaligned prints. Over time, belts can stretch or wear out, resulting in imprecise movements. Inspect the belts regularly to ensure that they are taut and properly tensioned. Belts that are too tight can also cause problems by putting excessive strain on the motors and bearings. Maintaining the correct belt tension is critical for consistent and accurate prints.

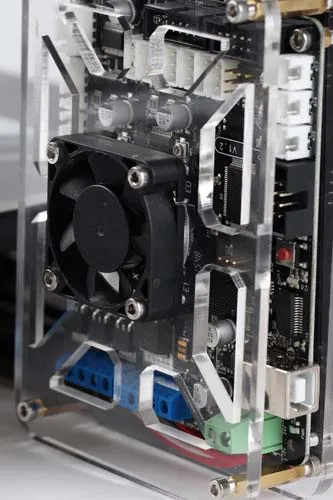

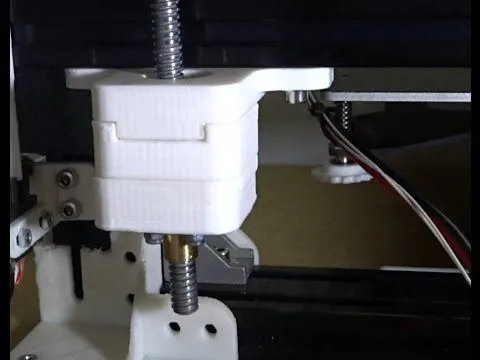

Stepper Motor Problems

The stepper motors are responsible for precisely controlling the movement of the print head and the print bed. If these motors malfunction or their drivers have issues, the print head may not move to the correct coordinates, resulting in an off-center print. Stepper motor problems can arise from various issues, including faulty wiring, overheating, or incorrect voltage settings. Check the wiring connections to the stepper motors and ensure they are secure. Additionally, verify that the motors are not getting excessively hot during printing, as this could indicate an overload. Correct operation of the stepper motors is crucial for the accurate positioning of the print head, and any problems can manifest as off-center prints or other positional errors.

Slicer Settings

Your slicer settings play a pivotal role in determining the print’s placement. Incorrect settings in the slicer program can lead to the printer misinterpreting the intended location. The slicer converts your 3D model into instructions that the printer can understand. Ensure the origin point of your model is centered in the slicer software. Verify that the bed size settings in your slicer match the actual dimensions of your Tevo Tarantula’s print bed. Incorrect settings here can tell the printer to start printing in the wrong spot. Make sure there are no offsets or other settings that could shift the print’s starting position.

Print Bed Adhesion and Warping

Poor adhesion of the first layer to the print bed can lead to warping, causing the print to lift from the bed and potentially shift position. This can give the impression of an off-center print. A dirty or improperly prepared print bed may reduce the adhesion of the first layer. Also, warping occurs when the print cools unevenly, causing stress on the edges. When the material cools unevenly, this stress can pull the print off-center or cause it to detach from the bed altogether. Clean the bed with isopropyl alcohol or a similar solvent before each print to remove any residue. Use adhesive materials like glue sticks or painter’s tape to improve adhesion and minimize warping.

Troubleshooting Steps to Center Prints

Once you’ve identified the potential causes, follow these troubleshooting steps to correct the off-center printing issues. A methodical approach will help you to pinpoint the exact cause and implement effective solutions. The process involves inspecting and calibrating various components of your Tevo Tarantula, starting with the print bed and moving on to the mechanics and settings. Remember, patience and attention to detail are your allies. Properly calibrating your printer and ensuring its mechanical components are in optimal condition is critical to fixing the problems that are causing the prints to be off-center.

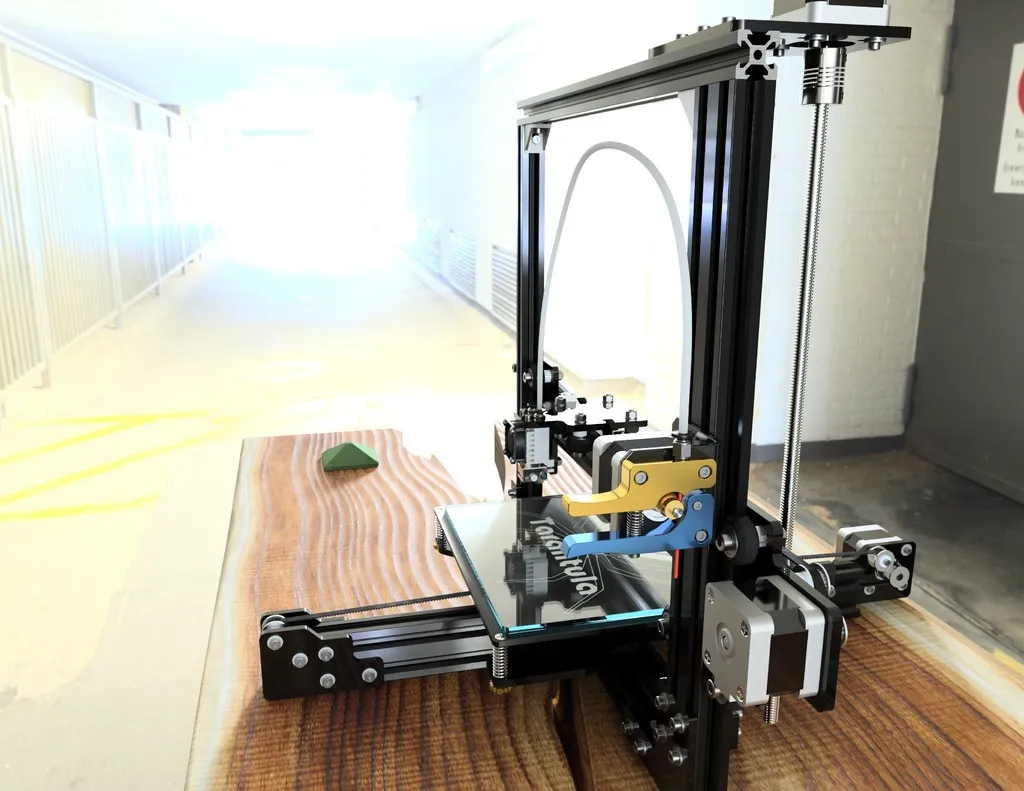

Leveling the Print Bed

Leveling the print bed is the first and most important step in troubleshooting off-center prints. Your Tevo Tarantula often has manual leveling screws at each corner of the print bed. Use a piece of paper or a feeler gauge to adjust the bed height at each corner until the nozzle lightly grazes the paper with a slight amount of resistance. Ensure that the bed is level in both the X and Y directions. For more advanced methods, many users upgrade to an auto-bed leveling system, which automates this process, providing a more consistent first layer. Proper bed leveling ensures that the nozzle maintains a consistent distance from the bed surface, which is crucial for print adhesion and dimensional accuracy.

Adjusting the Z-Offset

The Z-offset fine-tunes the nozzle’s distance from the print bed. After leveling the bed, adjust the Z-offset in your printer’s firmware or through the printer’s control panel. During the first layer printing, observe the filament flow. The nozzle should be close enough to the bed that the filament is slightly squished, but not so close that it clogs the nozzle or scratches the bed. A properly set Z-offset ensures that the first layer adheres well without causing the nozzle to scrape the print bed. If the Z-offset is incorrect, the print may not stick to the bed, or the nozzle may scrape the print bed. The ideal Z-offset varies slightly depending on the material, so be prepared to make minor adjustments for different filaments.

Tightening Belts and Pulleys

Inspect and tighten the belts and pulleys on your Tevo Tarantula. Loose belts can cause the print head to move imprecisely, leading to off-center prints. Check the X and Y-axis belts for any slack, and tighten them using the appropriate adjustment screws. Make sure the pulleys are securely attached to the stepper motor shafts and that there is no play. Ensure the belts are not overly tight, as this can damage the motors or bearings. You should be able to gently pluck the belts and hear a clear, distinct sound. If the belts are too loose, the print head’s movements will be imprecise, and this will be evident in the off-center prints.

Checking Stepper Motors

Ensure the stepper motors are functioning correctly. The stepper motors are the backbone of your 3D printer’s positioning system. Check the wiring to the stepper motors, and verify the connections are secure. Listen to the motors during operation for any unusual noises, which could indicate a problem. Overheating can cause stepper motors to lose steps and cause prints to shift. Ensure proper cooling and that the motors are not overloaded. The steppers should move smoothly without skipping steps. Any stuttering or uneven motion will manifest as inaccuracies in print positioning.

Reviewing Slicer Settings

Review your slicer settings to ensure the print is being positioned correctly. Double-check the bed size settings, and confirm they match the actual dimensions of your Tevo Tarantula’s print bed. Verify the origin point in the slicer. Make sure the model is centered on the virtual build plate. Review any offset settings, and make sure there aren’t any that could be causing the print to be shifted. Also, review your print profiles for any settings that could contribute to positional errors. Incorrect slicer settings can be a common and easily overlooked cause of print misalignment. Correctly configuring your slicer can solve many of the problems causing your Tevo Tarantula to print off-center.

Print Bed Preparation

Proper bed preparation is another critical step. A clean and well-prepared bed helps ensure good adhesion and reduces the likelihood of prints shifting during printing. Clean the print bed with isopropyl alcohol before each print to remove any oils or debris. You may also need to use an adhesive such as glue stick or painter’s tape to improve bed adhesion, especially with materials like ABS. Ensure the bed surface is level and free of any obstructions that could interfere with the print’s initial layers. The print bed’s condition greatly affects the first layer’s adhesion, which dictates whether the print will be centered, as well as the overall success of the print.

Calibrating the X and Y Axis

Calibrating the X and Y axes is essential for accurate print positioning. This calibration ensures the printer moves the print head the correct distance in both directions, matching the dimensions of your model. To start, you can print a test cube or calibration object and measure the dimensions of the print with calipers. Compare the printed dimensions with those specified in the 3D model to determine if the printer is over- or under-extruding, leading to dimensional inaccuracies. Any deviations indicate that the printer might be experiencing issues with its linear movement. The calibration is not only important for centering the prints but for the overall precision of the printing process.

Software Calibration

Software calibration involves adjusting the settings within your slicer to ensure correct dimensional accuracy. Within your slicer software, there are settings for steps per millimeter for the X and Y axes. These values determine how many steps the stepper motors take to move the print head a specified distance. Measure a known distance that the printer is supposed to move and compare it to the actual distance. If there is a discrepancy, you’ll need to adjust the steps per millimeter settings. Recalibrate the steps per millimeter settings for both the X and Y axes. Recalibration ensures the printer accurately translates the G-code instructions into physical movements on the print bed.

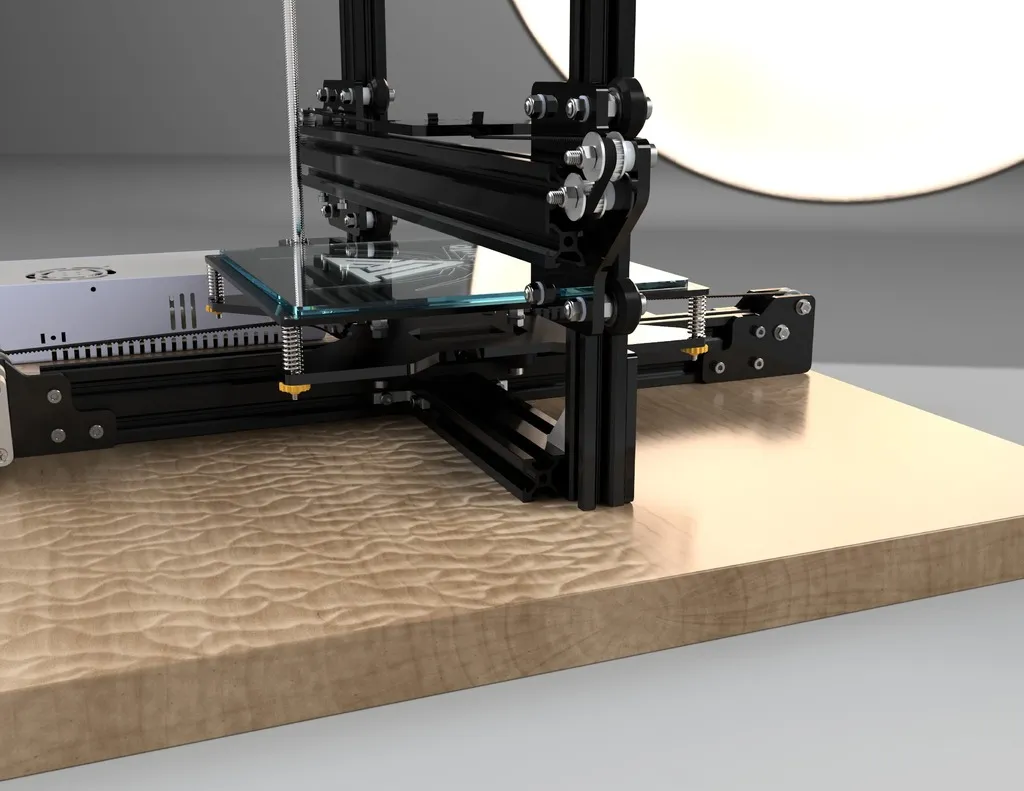

Hardware Calibration

Hardware calibration involves checking the mechanical components of the printer to ensure they are in good condition and correctly assembled. This may involve inspecting the belts, pulleys, and linear rails to ensure smooth and accurate movement. Check the alignment of the belts and pulleys to ensure they are parallel and that they are not rubbing against the frame or other components. Make sure the linear rails are properly lubricated, allowing the print head to move freely. Any issues with the hardware components could affect the dimensional accuracy of your prints. Regular inspections and maintenance of the hardware components are vital to maintaining accurate printing.

Preventative Measures for Centered Prints

Preventing off-center prints is about proactive maintenance and consistent monitoring of your printer. Establishing good habits for your 3D printing setup will minimize the chances of encountering this issue. By integrating preventative measures into your printing routine, you can ensure consistent, reliable, and accurate prints over time. These measures include regular maintenance, proper filament storage, and consistent monitoring of print quality. These small steps make sure that the Tevo Tarantula is always ready for use. These practices minimize the chance of your prints coming out off-center and save time and material.

Regular Maintenance

Regular maintenance is key to preventing off-center prints. This includes lubricating the moving parts of your printer, such as the linear rails and threaded rods, with appropriate lubricants. Regularly clean the print bed to maintain good adhesion, and inspect the belts and pulleys for wear and tear. The printer’s components need to be regularly inspected for wear and tear to ensure your printer performs reliably. It ensures that the printer operates smoothly and the print head moves to the correct coordinates. By establishing a regular maintenance schedule, you can keep your Tevo Tarantula in excellent condition, reducing the likelihood of print problems.

Proper Filament Storage

Storing your filament properly will help prevent print quality issues that could lead to off-center prints. Keep the filament in a cool, dry place away from direct sunlight and moisture. Over time, filament can absorb moisture from the air, leading to printing problems. When the filament is exposed to moisture, it can cause poor adhesion, warping, and other issues that may impact the print’s accuracy. Using a sealed container or desiccant can help keep your filament dry. Using a dry box ensures the filament is protected from the environment, which can contribute to a successful print.

Monitoring Print Quality

Consistently monitoring the quality of your prints is crucial to catching any problems early. Watch the first layer adhesion and the overall print quality closely. Look for any signs of warping, shifting, or other imperfections. Regularly calibrate your printer and make adjustments as needed. Run test prints regularly to check the printer’s calibration and accuracy. Keeping a log of your settings and print results can help track any changes and identify potential issues. By staying attentive to the quality of your prints, you can take early steps to fix any developing problems, and your 3D printing process will remain smooth.

In conclusion, off-center printing on your Tevo Tarantula is a common issue that can be resolved with careful troubleshooting and preventative measures. By addressing the common causes, implementing the troubleshooting steps, and practicing preventative measures, you can ensure your prints are accurately centered every time. Remember that a well-maintained and calibrated printer is the foundation of successful 3D printing.