Benefits of Carbon Fiber for Tevo Tarantula

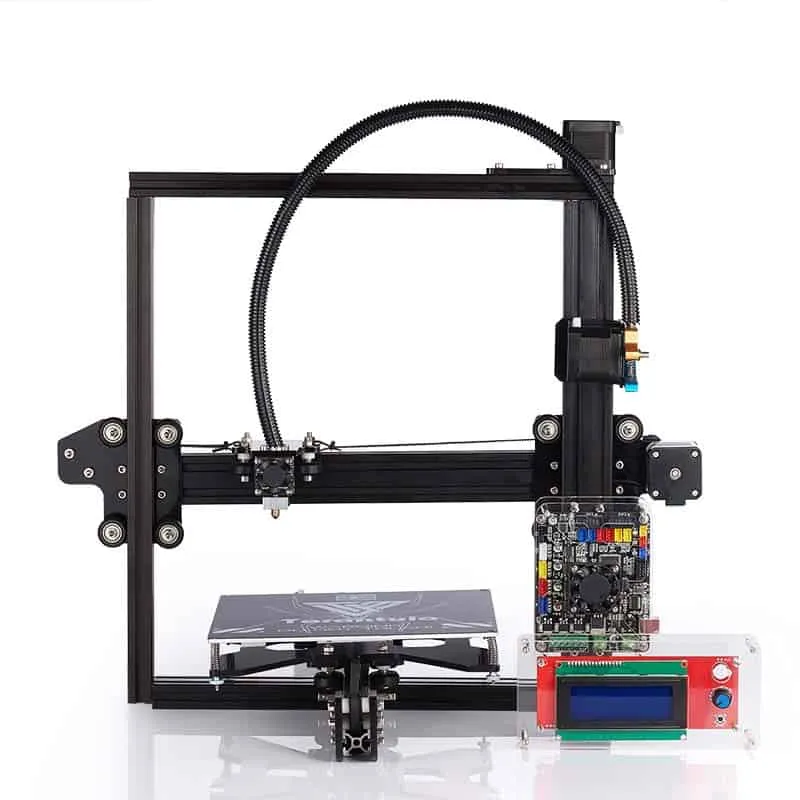

The Tevo Tarantula, a popular 3D printer among hobbyists, can be significantly enhanced with carbon fiber upgrades. These upgrades offer a range of advantages, from improved print quality to increased printer longevity. Carbon fiber’s unique properties make it an ideal material for enhancing the performance of your Tevo Tarantula. By integrating carbon fiber components, you can unlock new levels of precision, speed, and durability in your 3D printing projects. This guide explores the top carbon fiber upgrades and how they can transform your Tevo Tarantula.

Enhanced Rigidity and Stability

Carbon fiber’s exceptional strength-to-weight ratio drastically improves the rigidity of the Tevo Tarantula’s frame. This added stability minimizes vibrations during printing, resulting in more accurate and consistent prints. The reduced flex in the frame allows for finer details and tighter tolerances, ultimately improving the overall quality of your 3D prints. By reinforcing key structural components with carbon fiber, you ensure your printer operates smoothly and reliably, even at higher speeds.

Reduced Weight for Faster Printing

Carbon fiber components are significantly lighter than their metal or plastic counterparts. This weight reduction is particularly beneficial for moving parts, such as the print head and bed. Less weight means the printer can accelerate and decelerate more quickly, leading to faster printing speeds without sacrificing print quality. The ability to print at higher speeds translates to increased productivity and shorter project completion times. By replacing heavy components with carbon fiber alternatives, you can significantly boost your Tevo Tarantula’s performance.

Improved Print Quality and Precision

The enhanced rigidity and stability provided by carbon fiber directly translate to improved print quality. Less vibration and flex in the frame mean that the print head can move more precisely, resulting in sharper details and cleaner lines. Carbon fiber’s dimensional stability also contributes to more accurate prints, as the material is less prone to warping or deformation due to temperature changes. The use of carbon fiber parts ensures that your 3D prints are of the highest possible quality, with exceptional detail and accuracy.

Top 5 Carbon Fiber Upgrades for Your Tevo Tarantula

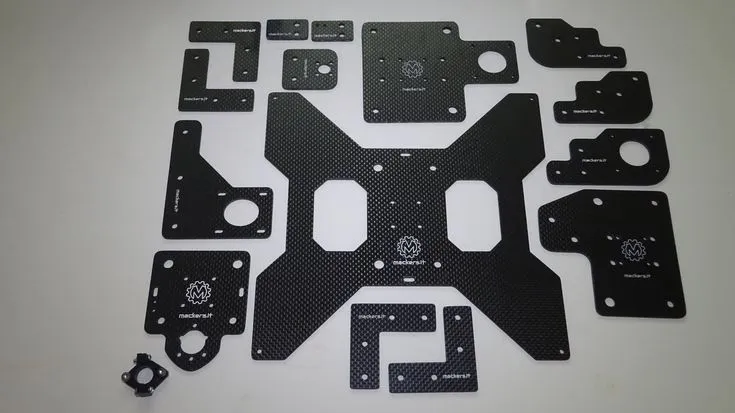

Carbon Fiber Frame Support

Adding carbon fiber frame supports is one of the most effective upgrades. These supports reinforce the printer’s frame, dramatically increasing its rigidity. They typically replace or supplement the existing metal or plastic frame components, providing superior stability and reducing flex. This upgrade is crucial for achieving high-quality prints, especially when printing at higher speeds or with demanding materials.

Carbon Fiber Hotend Components

Upgrading to carbon fiber hotend components can enhance the performance and durability of your printer’s hotend. Carbon fiber heat breaks and nozzles offer excellent thermal properties, improving heat distribution and reducing the risk of clogs. These components also offer increased resistance to wear and tear, extending the lifespan of your hotend. By incorporating carbon fiber in the hotend, you can improve printing consistency and reliability.

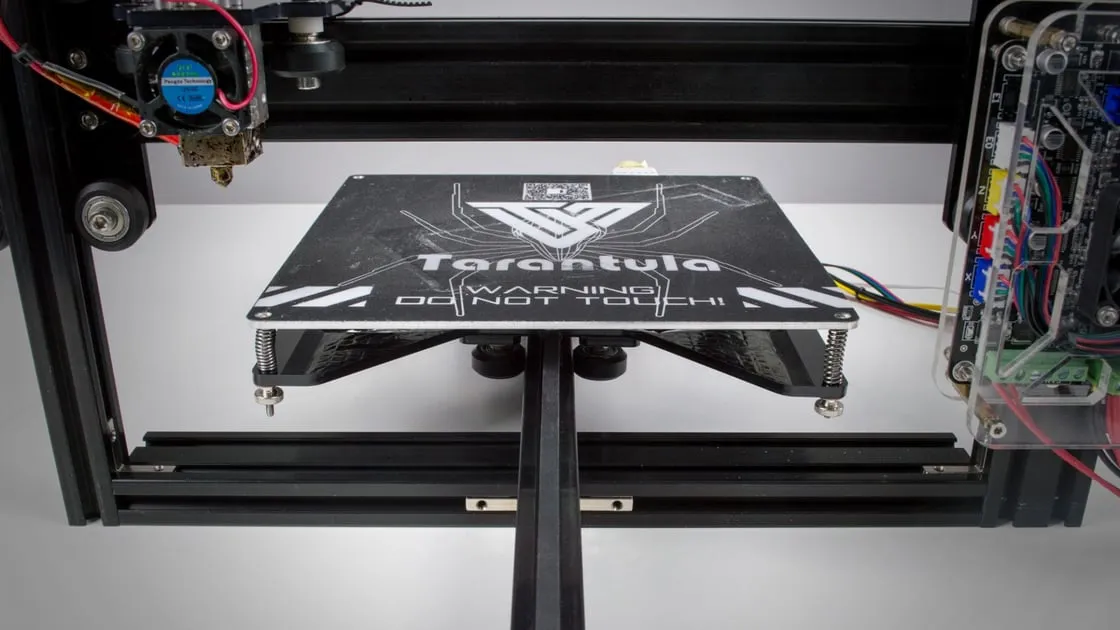

Carbon Fiber Bed Support

A carbon fiber bed support offers increased stability for your printer’s print bed. This upgrade minimizes vibrations and ensures the bed remains level during printing. A stable print bed is essential for consistent first-layer adhesion and overall print quality. Carbon fiber bed supports help to maintain a consistent printing surface, providing an ideal foundation for your 3D prints.

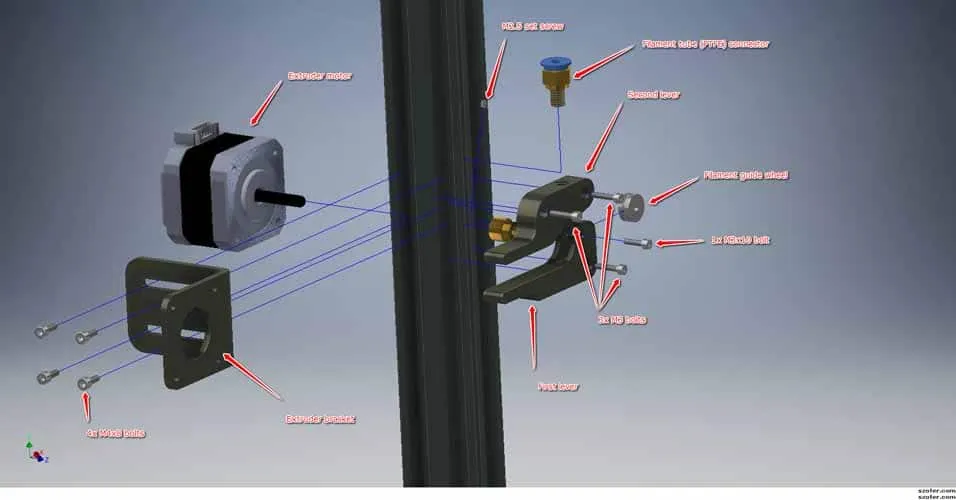

Carbon Fiber Extruder Upgrades

Carbon fiber extruder upgrades, such as extruder arms and housings, provide improved performance and durability. These upgrades reduce the weight of the extruder, allowing for faster and more precise movements. The increased rigidity minimizes flex, resulting in more consistent filament feeding. Carbon fiber components in the extruder ensure reliable and efficient filament management.

Carbon Fiber Filament

Using carbon fiber-infused filament can provide excellent results. This filament combines the strength of carbon fiber with the ease of printing of standard materials. Prints made with carbon fiber filament are known for their strength, stiffness, and dimensional accuracy. Choosing carbon fiber-infused filament allows you to produce high-quality prints with enhanced mechanical properties, ideal for functional parts and demanding applications.

Installation Guide for Carbon Fiber Parts

Preparing Your Tevo Tarantula

Before installing any carbon fiber upgrades, make sure your Tevo Tarantula is powered off and unplugged. Gather the necessary tools, including Allen wrenches, screwdrivers, and any other tools required for the specific upgrades. Refer to the manufacturer’s instructions for each carbon fiber part you are installing. Proper preparation is key to a successful and smooth upgrade process.

Installing Frame Supports

Carefully remove the existing frame components according to the instructions provided with the carbon fiber frame supports. Align the new carbon fiber supports with the frame and secure them using the provided hardware. Ensure the frame supports are firmly attached and that the printer’s frame is aligned correctly. Double-check all connections to ensure everything is secure before proceeding.

Upgrading Hotend Components

Carefully disassemble your hotend, following the manufacturer’s instructions. Replace the existing components with the carbon fiber hotend components. Ensure that the new components are properly seated and secured. Reassemble the hotend and ensure that the nozzle is properly tightened. Test the hotend to ensure there are no leaks and that it is heating up correctly.

Calibrating and Testing

After installing the carbon fiber upgrades, carefully calibrate your printer. This includes leveling the print bed, adjusting the Z-offset, and calibrating the extruder. Perform a test print to assess the results and make any necessary adjustments. Fine-tuning your printer’s settings is crucial for achieving optimal print quality and ensuring the upgrades are performing as intended.

Maintaining Your Carbon Fiber Upgrades

Regular Inspection and Cleaning

Regularly inspect your carbon fiber components for any signs of wear or damage. Clean the components with a soft cloth and appropriate cleaning solutions. Avoid using harsh chemicals that could damage the carbon fiber. Proper maintenance ensures that your upgrades continue to perform optimally and extends their lifespan.

Proper Filament Storage

Store your carbon fiber-infused filament in a dry, airtight container to prevent moisture absorption. Moisture can negatively affect the printing quality of the filament. Consider using desiccant packs to further protect the filament from humidity. Proper filament storage is essential for achieving consistent and high-quality prints.

Troubleshooting Common Issues

If you encounter any issues, such as poor print quality or clogs, consult the troubleshooting guides provided with your carbon fiber upgrades. Check the printer’s settings, nozzle temperature, and bed leveling. If problems persist, seek assistance from online forums or contact the manufacturer for support. Proper troubleshooting can help you resolve issues quickly and maintain optimal printing performance.

Conclusion

Upgrading your Tevo Tarantula with carbon fiber parts is a fantastic way to enhance its performance and print quality. From improved frame stability to better print precision, carbon fiber offers significant advantages. By implementing these upgrades and following the installation and maintenance tips, you can transform your Tevo Tarantula into a high-performance 3D printer. Embrace the power of carbon fiber and experience a new level of 3D printing excellence.