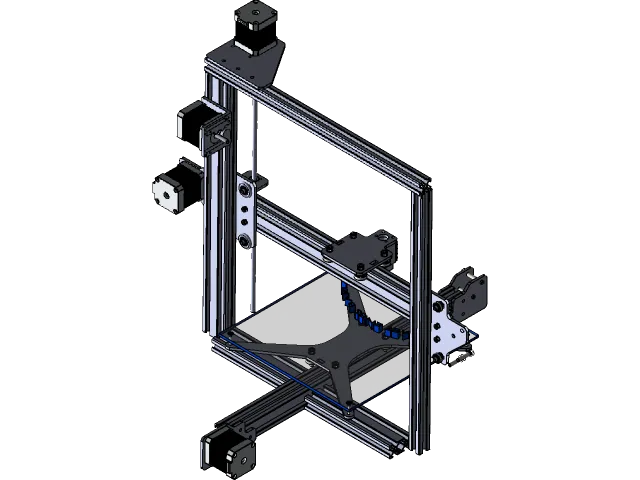

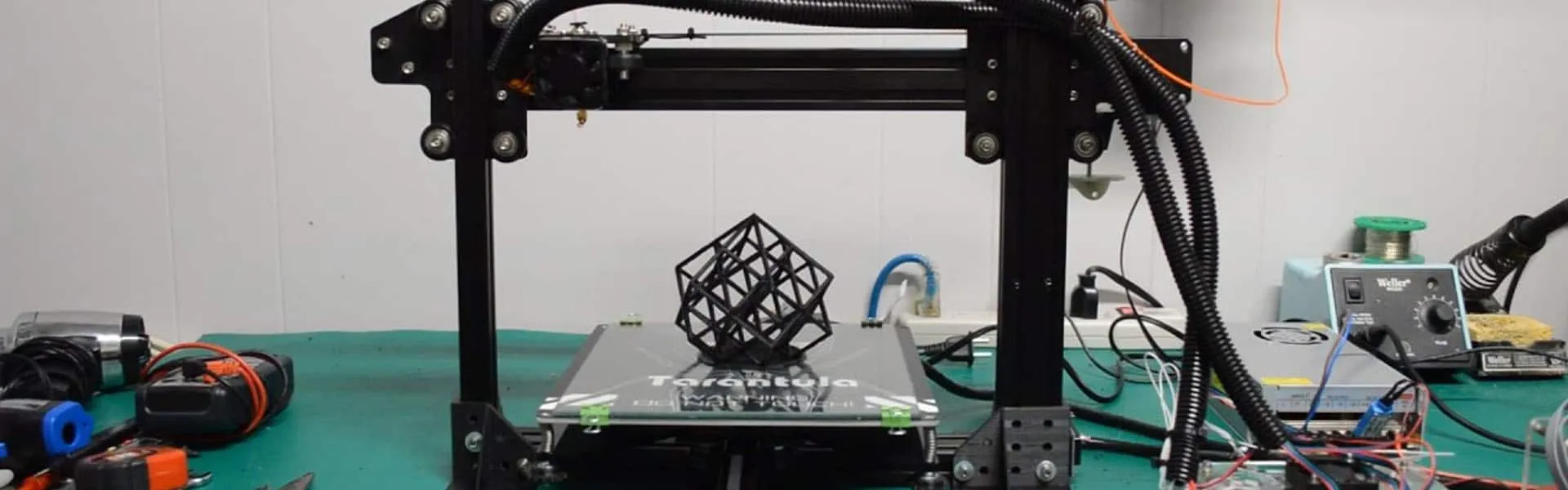

Tevo Tarantula UK Top 5 Tips!

The Tevo Tarantula has become a popular choice in the UK for 3D printing enthusiasts, especially those starting their journey into the world of additive manufacturing. Its affordability and open-source nature make it an attractive option, but getting the best results requires understanding some key aspects. This guide focuses on the top 5 tips to help you maximize your Tevo Tarantula 3D printer’s potential, ensuring successful prints and a satisfying 3D printing experience. Whether you’re a complete beginner or have some experience, these tips will help you improve your print quality and overall satisfaction with your Tevo Tarantula in the UK.

Tip 1 Leveling the Bed

Bed leveling is the cornerstone of successful 3D printing. It ensures that the first layer of your print adheres properly to the print bed, which is critical for the entire print’s structural integrity. Inconsistent bed leveling often leads to warping, poor adhesion, and print failures. With the Tevo Tarantula in the UK, you’ll want to pay close attention to this step, as even slight misalignments can cause significant issues. Take the time to level your bed precisely before each print, or invest in an auto-leveling system for added convenience. This single step is often the difference between a successful print and a frustrating experience. This step is the first step on the Tevo Tarantula in the UK that needs to be set up before the first print can start. Always check the level before the printer starts to print.

Why Bed Leveling is Crucial

Proper bed leveling ensures the nozzle is at the correct distance from the print bed across the entire surface. If the nozzle is too far, the filament won’t stick. If it’s too close, the nozzle can scratch the bed, or the filament will extrude improperly. The Tevo Tarantula in the UK, like many 3D printers, relies on this precise calibration. This precision directly impacts the quality of your prints. Understanding why bed leveling is so crucial is the first step in achieving consistently high-quality prints. The first layer sets the foundation for the entire print; any flaws here will propagate upwards, leading to defects in the final product. This is why it is the first item on our guide, and the Tevo Tarantula in the UK needs it the most.

Leveling Techniques

There are several methods for leveling the bed of your Tevo Tarantula in the UK. The most common method is using the paper test. Place a piece of paper between the nozzle and the bed, and adjust the bed’s leveling screws until the nozzle slightly grips the paper as you move it around. Another method is to use a feeler gauge. For more advanced users, many opt for auto-leveling sensors that automate the process. No matter the method, ensure that the bed is level across all points. Several online resources and videos are available to guide you through these leveling techniques, making the process easier for beginners. The use of the paper method is the most popular method for the Tevo Tarantula in the UK.

Tip 2 Filament Selection

Choosing the right filament is essential for achieving the desired results with your Tevo Tarantula in the UK. Different filaments offer various properties in terms of strength, flexibility, and ease of printing. Some common filament types include PLA (Polylactic Acid), ABS (Acrylonitrile Butadiene Styrene), PETG (Polyethylene Terephthalate Glycol), and TPU (Thermoplastic Polyurethane). PLA is often recommended for beginners due to its ease of use and low warping tendencies. ABS offers greater strength and durability but requires a heated bed and can be more prone to warping. PETG combines the best of both worlds, offering good strength and flexibility with less warping. TPU is a flexible filament used for creating rubber-like parts. When selecting a filament for your Tevo Tarantula in the UK, consider the specific requirements of your project.

Best Filament Types for Tevo Tarantula

For beginners in the UK using the Tevo Tarantula, PLA is often the go-to filament. It’s easy to print with, doesn’t require a heated bed in most cases, and is available in a wide range of colors and finishes. ABS can be used for stronger parts, but it requires more precise temperature control and often benefits from an enclosure to prevent warping. PETG is a good middle ground, providing a balance of strength, flexibility, and ease of printing. It’s less prone to warping than ABS and offers better durability than PLA. For more advanced users, TPU can be used to create flexible parts. Experimenting with different filaments will help you discover the best options for your specific needs and projects, but PLA is a good starting point for the Tevo Tarantula in the UK.

Filament Storage Tips

Filament storage is a critical, yet often overlooked, aspect of 3D printing. Filament, particularly hygroscopic materials like nylon and PETG, can absorb moisture from the air, leading to print quality issues such as stringing, poor layer adhesion, and nozzle clogs. To prevent this, store your filament in a dry, airtight container. Silica gel packets can be added to absorb any moisture that may be present. When you’re not using the filament, keep it sealed in a bag or container to prevent it from being exposed to humidity. Proper storage ensures that your filament remains in optimal condition, leading to better print quality and fewer headaches. Proper storage will improve your Tevo Tarantula in the UK’s quality of prints.

Tip 3 Slicing Software Settings

Slicing software is the bridge between your 3D model and your Tevo Tarantula in the UK. This software converts your 3D model into G-code, the instructions that the printer follows to create your object. The settings within the slicer significantly impact the quality, speed, and success of your prints. Understanding and optimizing these settings is crucial for getting the best results. It is important to experiment with different settings to find what works best for your chosen filament and specific 3D model. When using the Tevo Tarantula in the UK, your slicer settings will be different to a more modern printer.

Recommended Slicer Software

Several slicer software options are available, each with its strengths and weaknesses. Cura is a popular choice, known for its user-friendly interface and extensive features. Simplify3D is another option, offering advanced settings and excellent print quality, though it comes at a cost. PrusaSlicer, developed by Prusa Research, is free and open-source, offering excellent features and is optimized for Prusa printers but works well with others. The choice of slicer often comes down to personal preference, but it’s essential to choose one that suits your skill level and the complexity of your prints. For the Tevo Tarantula in the UK, Cura is a great place to start due to the user-friendly interface and the availability of profiles specifically designed for the printer.

Key Slicer Settings to Optimize

Several slicer settings impact the print quality. Layer height determines the resolution of your print. Lower layer heights provide smoother surfaces but take longer to print. Print speed affects the speed at which the nozzle moves, impacting print time and quality. Infill density determines how solid the inside of your print is, affecting its strength and material usage. Temperature settings (nozzle and bed) are crucial for proper filament melting and adhesion. Retraction settings prevent stringing. Experiment with these settings to find the optimal combination for your filament and model. The best settings depend on your specific model and filament, but understanding the impact of each setting is essential for fine-tuning your prints. The more you experiment with your Tevo Tarantula in the UK, the easier these settings will get.

Tip 4 Maintenance and Upgrades

Regular maintenance and strategic upgrades are essential for keeping your Tevo Tarantula in the UK running smoothly and producing high-quality prints. Regular maintenance prevents issues and prolongs the printer’s lifespan. Upgrades improve performance and often address the limitations of the original design. By following a maintenance schedule and considering worthwhile upgrades, you can ensure your printer remains reliable and produces excellent results. The maintenance and upgrades of the Tevo Tarantula in the UK will impact your experience.

Routine Maintenance Checklist

A regular maintenance schedule should include tasks such as cleaning the print bed, lubricating moving parts, and checking belt tension. Clean the print bed after each print to ensure good adhesion. Regularly lubricate the Z-axis lead screws and other moving parts to prevent wear and tear. Check the belt tension on the X and Y axes, as loose belts can cause print quality issues. Inspect the nozzle for clogs and clean it as needed. These simple maintenance tasks will prevent many common problems and keep your printer in good working order. Regular maintenance on your Tevo Tarantula in the UK will ensure it runs smoothly.

Essential Upgrades for Better Prints

Several upgrades can improve your Tevo Tarantula’s performance. Upgrading to a glass bed provides a more level and stable printing surface, and is highly recommended. Replacing the stock hotend with an all-metal hotend allows you to print at higher temperatures and with a wider range of filaments. Installing a MOSFET for the heated bed can improve safety and reliability. Adding a BLTouch auto-leveling sensor simplifies bed leveling. Other upgrades include improved cooling fans, belt tensioners, and a better power supply. Consider these upgrades to enhance your printer’s capabilities and print quality, improving the performance of your Tevo Tarantula in the UK.

Tip 5 Troubleshooting Common Issues

Even with careful preparation, you may encounter issues while 3D printing with your Tevo Tarantula in the UK. Understanding common problems and how to address them is essential for a smooth 3D printing experience. This section covers the troubleshooting for common problems and will help you to resolve them quickly. By understanding the potential issues and how to resolve them, you can save time and frustration. The Tevo Tarantula in the UK may require some troubleshooting, but with time, you will get to know your printer.

Addressing Common Print Problems

Common problems include poor bed adhesion, warping, stringing, and nozzle clogs. Poor bed adhesion can be resolved by leveling the bed correctly, cleaning the bed surface, and using an appropriate bed adhesive (glue stick, hairspray). Warping can be addressed by using a heated bed (if your filament requires it), ensuring proper bed adhesion, and using an enclosure. Stringing can be fixed by adjusting retraction settings and temperature. Nozzle clogs can often be cleared by performing a cold pull or using a nozzle cleaning tool. Identifying the problem correctly is the first step in resolving it. Many online resources and troubleshooting guides are available to help you diagnose and fix these issues. The community will know what to do to resolve common issues with the Tevo Tarantula in the UK.

Software and Hardware Troubleshooting

Troubleshooting often involves both software and hardware aspects. If you’re experiencing print quality issues, first, check your slicer settings, filament type, and printer temperatures. Make sure your firmware is up-to-date. Then, inspect the hardware, including the nozzle, bed level, belts, and moving parts. Check for any loose connections or mechanical issues. If you suspect a hardware problem, consult the printer’s manual or seek assistance from online forums. By systematically checking both software and hardware, you can often pinpoint the cause of your problem and find a solution. The Tevo Tarantula in the UK has a large community that can also help with troubleshooting.